Summary:

- Project designers often find their structure impacted by ADA slope regulations, a 100 year flood event, or other clearance mandates.

- American Disabilities Act may impact your project in other ways. Our bridges are designed on a “circular” curve, so just because ADA allows for a 5% (or 8.33% with a pipe handrail) slope, it doesn’t mean a 100’ bridge can have a 2.5’ rise in the center vs. the ends, and still meet ADA compliance.

- This industry expresses bridge arch (i.e. camber), as a percentage of length vs. the rise at the center (Example: 1% camber on a 100’ span, would mean the center of the bridge is 1’ higher than the ends)

- Stream loads need to be investigated if the bridge will be fully or partially inundated. We would need to know the stream load (in feet per second), and how much of the bridge will be inundated in a flood event, in order to provide accurate pricing. Stream loads can SIGNIFICANTLY affect your bridge price, weight, etc…

- Skewed ends on a bridge (to accommodate crossing at a non-square angle), potential freezing rain, and accumulating snow can also be a cause for design change considerations.

The Squeeze: Because the American Disabilities Act (ADA) limits a trail surface or ramp to a maximum 5% slope (or in some circumstances 8.33%,) it can become problematic, or just plain expensive, to raise the travel surface enough to provide adequate clearance, that may be required for your site specific scenario. Excel Bridge recommends you be alert for this potential issue. One fact that is not always apparent is that these bridges can often accommodate unequal elevations at each abutment (assuming this elevation difference isn’t in combination with skewed ends). With elevation differences, typically just specify “dead load camber only” (i.e a flat bridge), and specify the amount of elevation difference from one end of the structure to the other. Please see more info. regarding ADA compliance and potential issues below.

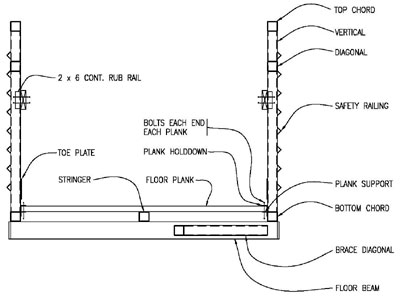

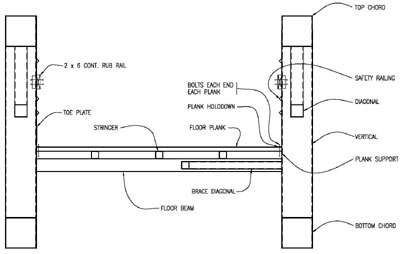

Below deck dimensions: Pony and Full Through “Box” trusses are typically the best fit for scenarios in where the “top deck to low steel” dimension is required to be minimal. A “Beam / Girder/ Stringer” type structure or a (Half-Through) “H-section” style span, has more limitations of the required top of deck to low steel dimension. Let Excel help you determine this measurement based on the particulars of your bridge requirements.

The “U” section configuration is only possible with shorter spans under 70-100 feet (depending on width & loading requirements). Top deck to low steel is often 11 1/4″ to 18″ (A “Box” style structure will often provide similar dimensions for longer spans). |

The “H” section is typically used for longer spans, heavier loadings, or to limit height or railings. Top deck to low steel dimensions may be 2′ to 7′. |

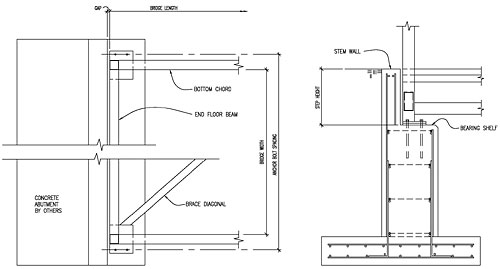

Above is a typical abutment plan and elevation view. The “step height” shown will vary with bridge particulars, please call for assistance. |

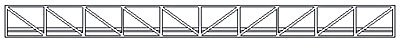

Bridge Arch: The pre-fabricated steel bridge industry defines “camber” as the amount of rise at the center of the span, divided by the length of the bridge. You will find that an approx. 1% camber yields around a maximum 5% slope at bridge ends, and approx. 2% camber yields closer to a 8.33% slope. Most engineers and architects seem to agree that regardless whether a project is required to meet ADA compliance, a 1-2% camber is the most aesthetically pleasing and comfort friendly choice. A quick calculation may show that the camber (arch) of the bridge is very little help to the designer to clear a certain required elevation.

Dead load camber only

Dead load camber only Approx. 1% camber (i.e., 5% slope)

Approx. 1% camber (i.e., 5% slope) Approx. 2% camber (i.e., 8.33% slope)

Approx. 2% camber (i.e., 8.33% slope)

Note that with our truss bridges, the camber is not a structural element. For a preference of a flat bridge, just specify “dead load” camber, and Excel will camber the bridge just enough to offset it’s own dead load + live load (bridge weight + the maximum allowed live load) – so the bridge will never have sag or what we call “negative” camber.

Stream Load: Be sure this issue is investigated. The designer generally has three choices when crossing water:

- Raise the abutments enough to clear the flood waters.

- Have the bridge designed to withstand flood forces, if the resulting back up or water flow diversion is acceptable. Sometimes stream flow of up to 12 fps can be accommodated, but this certainly affects the price in a significant way, and as the structure gets longer, the less stream load the bridge can be designed to withstand.

- Design the bridge as a “break-a-way”. Most engineers specify the bridge manufacturer to provide a large diameter cable attachment bracket under the bridge at one end. This way, if the bridge is washed off it’s abutments, the structure can often be set back in place. But damage or complete destruction of the structure is common as well. The theory behind the cable is to prevent the bridge from rolling downstream in a flood event, and thus potentially injuring someone or creating another restriction to flow, and hopefully lessen the damage to the bridge.

American Disabilities Act: In addition to the “Bridge Arch” discussion above, a project designer needs to consider several other bridge and ramp issues. If there are no reasonable alternative routes for the disabled, ADA law may apply:

- If a bridge has unequal abutment elevations, effectively making it a ramp, it should be specified as “dead load” camber ( i.e. flat), or “Slope per maximum ADA compliance, taking into account the elevation difference”.

- If the ramp effect or camber causes a slope over 5%, accessible ADA compliant pipe handrails must be included. If the 5-8.33% slope continues further than 30′, a 5′ level landing must be designed into the bridge deck. ADA does not allow slopes over 8.33%.

- Often; ramps for highway or RR overpasses are constructed partly or completely of earthwork and concrete. However, sometimes it is less expensive and/or creates less impact to the environment to use ADA compliant stand alone ramps for the upper sections. Please call and we can help you with this determination.

Snow Loads: In mountainous areas, many National Parks have observed a multiplied load due to snow cohesion when a bridge is buried in snow. Essentially what this means is; the bridge is not only affected by the snow directly above the deck area, but also the applied load from any adjoining snow that adheres to the snow on the deck, and sort of cantilevers off the edges of the bridge. Some areas of the country now specify 250 psf snow load & up to accommodate huge snow average totals and this can greatly affect the design & price of the structure.

Freeze damage: Specifying drain holes is highly recommended, as in some instances, the structural tubular members may partially fill with water over time, and if that water freezes, it can deform or even burst open the tubular member in which the frozen water is contained.

Skewed ends: If your project requires one or both ends of a bridge to be skewed (in other words; skewed from a plan view), be aware that it can add several thousand dollars for each skewed end, and sometime cause other related difficulties. When possible, often a better (or more economical) solution is to skew the abutment bearing shelf(s) in relation to the area you’re crossing, and leave the bridge ends square, versus skewing the ends of the bridge.

Longevity: Other forms of construction, such as wood bridges usually do not last as long as steel, usually require piers, and the railings require regular maintenance.